THE PRESSURE REDUCING VALVE : DEFINITION

This valve reduces the pressure of the water that goes through it, and is used to obtaining a regulated and constant value at its outlet.

It is installed at the water mains (for a bungalow as for a flat). It protects the whole installation from problems due to excess pressure : noises in the pipes, water hammer, splashes, premature wear of household electrical appliances and taps.

The pressure reducing valves are completely automatic.

PRESSURE REDUCING VALVES OR REGULATORS ?

We use the standardised official term « REDUCER », but a pressure reducing valve is highly sensitive to upstream pressure variations, and regulates badly without water flowing (without drawing).

The WATTS INDUSTRIES direct action pressure reducing valves (PRECISIO, U5B, REGLEAU) regulate the downstream pressure as well with or without water flowing (without drawing). The downstream pressure only varies by 8% from the upstream pressure variation. These appliances are therefore PRESSURE REGULATORS.

WATTS, THE INVENTOR OF THE REGULATOR

• In 1876 : Invention, manufacturing and marketing of the first regulator.

It was somewhat complicated, took up a lot of space (nearly 2 metres high), but it worked.

• 1930 : A half century had already gone by.

Everything was designed

the principle of the direct action regulator with diaphragm operating the flap valve, the interior shape, the general look.

• From this date, most regulators made in the world were inspired by or copied this format.

The unique design of the WATTS pressure reducing valve makes it insensitive to scale or impurities, and needs no maintenance.

The diaphragm, spring, seat and flap valve are largely dimensioned for precise and constant regulation all in allowing high flow rates.

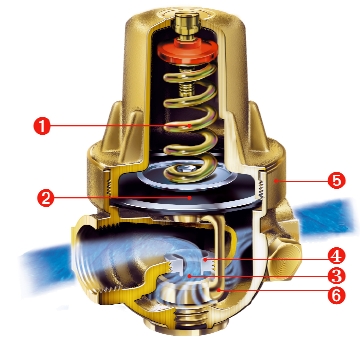

A corrosion-free spring (1) with a large spiral and highly sensitive :

it guarantees precise adjustment. The pressure control is within

the 1,5 to 5,5 bar range.

A high-temperature diaphragm (2) and a flap valve (3)

resist high

temperatures (up to 80°C).

A stainless steel seat (4) : an exclusivity that protects from

wear and water aggressivity. Give a long-life guarantee.

A single-unit body in non-dezincificable brass (5) (DZR) :

highly robust, this metal is resistant to corrosion and

satisfies the new health standards on the compatibility of

materials in contact with drinking water.

A yoke and flap valve assembly (6) : single-piece moving

part in non-dezincificable brass (DZR), the yoke includes

a flap valve (3) that is largely dimensioned, allowing higher

performance to standard requirements.

PRECISIO, U5B and REGLEAU use this direct action technique, with yoke and diaphragm.

HOW TO CHOOSE THE DIAMETER OF PRESSURE REDUCING VALVES ?

Practical rule : the pressure reducing valve is generally chosen according to the diameter of the installed pipe, provided, of course, that the latter is of the right size.

The choice of pipe diameters must follow the rules of the trade and must conform to the standards in force.

Refer to the flow rate curves of each pressure reducing valve, given in the technical documents.

INSTALLATION

WATTS pressure reducing valves may be installed in all positions.

They are generally installed directly after the water meter, and thus protect the whole installation.

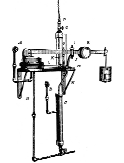

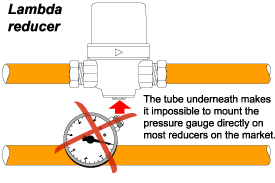

PRECISIO has 2 side connections and not a single one under the appliance

unlike similar valves offered in the market.

Advantage of a pressure gauge connection on the front : when 2 tubes are parallel with the wall, one above the other.

HOW TO ADJUST A PRESSURE REDUCING VALVE ?

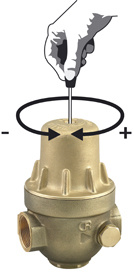

THE ADJUSTMENT MUST BE DONE WITHOUT FLOW — NO DOWNSTREAM OUTFLOW.

The WATTS INDUSTRIES pressure redicing valve are factory preset at 3 bar.

They remain adjustable within a 1,5 to 5,5 bar range.

• To increase the pressure, tighten the adjusting screw (clockwise as you look at the screw from above).

• To reduce the pressure, undo the adjusting screw

(anticlockwise as you look at the screw from above),

slightly open a tap for a moment, close again, then tighten the screw again

until you obtain the desired pressure.

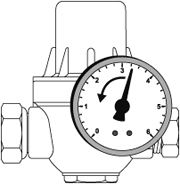

Two 1/4" gauge ports are located on each side of the valve when

a pressure gauge is required to be fitted.

| When opening the downstream tap (drawing), it is normal to see the pressure drop : this is the load loss of the appliance.

This value is given in the appliance flow rate curves (see technical documents). |

|